Contact us

South China

:48 Hongjin Road, Hongmei Town, Dongguan City, Guangdong Province, China

:15625731224 (Miss He)

:zdh.23@kobarry.com

East China

:No.6 ZengRoad, Lujia Town, Kunshan City, Jiangsu Province

:13428936677(Mr.Xiong)

:sales01@kobarry.com

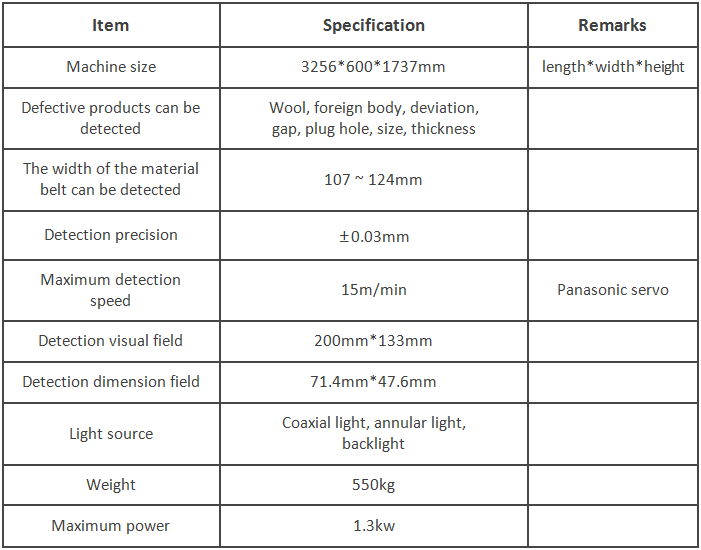

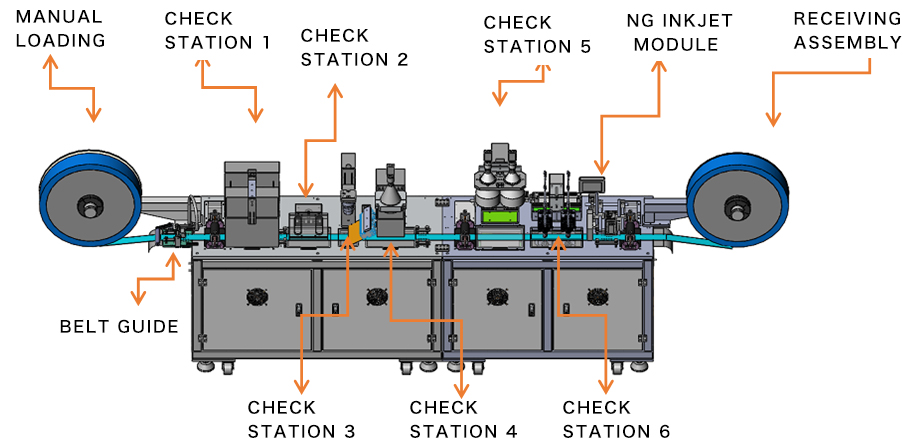

The equipment can realize stable and accurate feeding by placing and receiving the material coil at both ends and matching with the servo motor pulling module. Equipped with six detection stations (camera light source combination) and coding parts, it can simultaneously detect the positive and negative appearance of the detected product, wool foreign body, glue overflow, glue deficiency, hole blocking, less material and more material, and product size. This automatic appearance detection machine is suitable for the appearance defect detection of 3C electronic gum products, mainly wool, foreign body, deviation, gap, plug hole, size, thickness and other defects.

Modular design: the use of multi-station layout, flexible configuration detection function;

Fast detection speed: the highest speed can reach 15 meters per minute;

NG product identification: after detection of defective products, it has the function of inkjet marking, which is convenient for the following stations to remove defective products;

Offline/online: can realize single machine production and online production or online production of multiple machines, can be connected with other adhesive equipment;

Detection accuracy: the use of upper and lower double position, 12 million pixel +20 million pixel high precision industrial camera and large area telecentric lens, high resolution, detection size accuracy can reach ±0.03mm; Equipped with high precision thickness detection instrument, detection accuracy can reach ±0.005mm.

Equipment description: Manually place the material tray to the feeding module and then pull the material belt through the guiding module of the material belt -- detection station 1 -- detection station 2 -- detection station 3 -- detection station 4 -- detection station 5 -- detection station 6 -- receiving component, start the equipment, the equipment can automatically feed detection.

When the NG product is found, the coding component will spray the NG product to facilitate the later personnel to quickly identify the NG product.